Deep Collaboration with Xinjiang Tianchuang Technology Co., Ltd.

We have established comprehensive industrial chain synergy with Xinjiang Tianchuang Technology Co., Ltd. and its strategic partner Xinjiang Zhichuang New Materials Co., driving the upgrading of rigid PVC foam industry through material technology revolution. The independently developed diethyl oxalate solvent by Xinjiang Zhichuang has overcome the technical limitations of traditional butyl acetate solvent. With 40% enhanced polarity matching with PVC resin molecular chains, it not only significantly reduces solvent volatilization temperature (from 120°C to 80°C) and decreases production energy consumption by 15%, but also achieves over 95% closed-cell rate through hydrogen bond directional binding technology. This material innovation enables Tianchuang's downstream ultra-light high-strength PVC structural core materials to achieve performance leaps: compression strength increased to 18MPa while density reduced to 80kg/m³, successfully entering high-end markets including aerospace and new energy ships. The jointly established "Solvent-Resin-Product" laboratory is optimizing raw material ratios through reverse engineering, with real-time stress distribution data from end products feeding back to upstream formula design, forming a closed-loop ecosystem between material development and product iteration.

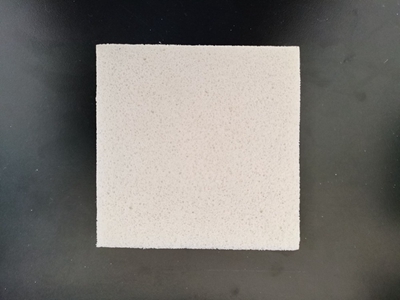

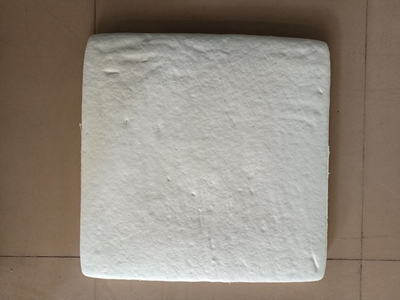

Structural foam board A Density 30kg/m³

|

Flame retardant foam board Density 50kg/m³

|

Flame retardant foam board Density 80kg/m³

|

Structural foam board B Density 30kg/m³

|